Everything You Need to Know About Hard Seltzers

Hard seltzers are everywhere these days. Most people probably think that White Claw is what started the trend, but the truth is, hard seltzers have been around for a long time. For example, remember Zima in the 90s? That was a hard seltzer line launched by Coors Brewing.

Regardless, the proliferation of hard seltzer – especially among millennials during the pandemic – has created a whole cottage industry of drinks. In fact, the truth is that hard seltzers are here to stay and not just some phenomenon. In 2019, for example, hard seltzers outpaced and outsold vodka in all age demographics, with over 2 billion cans sold.

That’s a ton of drinks sold over-the-counter, and it doesn’t even consider the number of drinks poured from a tap. The sheer numbers prove one thing about hard seltzers. They’re here to stay. But have you ever considered what is a hard seltzer and how it’s made?

A Quick One While He’s Away

Hard seltzers are as easy to make as they are to drink. At around 100 calories and 2 grams of sugar per 12 oz pour, a hard seltzer is a perfect alternative to a light beer and is much more flavorful.

As opposed to light beer loaded with carbohydrates and sugars, usually to the tune of 150-240 calories from carbohydrates and 40 grams of sugar in beer, the light, refreshing hard seltzer is a great way to relax without packing on the pounds. There are even gluten-free versions that are on the market!

The Brewing Process for Hard Seltzer

Hard seltzer, in a nutshell, is made from fermented cane sugar, malted barley, or even vodka. The official designation of hard seltzers is flavored malt beverages (FMB) as they are made with fermented barley or sugar, are flavored, and have low-carb levels.

For the restaurateur, adding hard seltzer to their lineup is a no-brainer. The ease of making hard seltzer, the profit margin possibilities, and popularity are some of the reasons you should consider making it in-house for your restaurant or bar.

The process of making hard seltzer is fairly straightforward:

- Start with water. To start, you need reverse osmosis or distilled water.

- Add the yeast. Once you have your water, pitch yeast with plenty of yeast nutrients – the sugar or barley – and let ferment.

- Let it ferment: The total time for fermentation should be about 2-weeks at 68-71 degrees Fahrenheit.

- Add the carbonation. After the fermentation process is over, the next step is to flavor and carbonate the beverage to get the delicious, fizzy drink that is a hard seltzer.

As you can see, there’s not much to making hard seltzers. And with the ease of production and low cost to make, if you run a restaurant or bar, you may want to explore the possibility of making your own. It could be a fun addition to your restaurant to make it stand out among your competitors.

The Canning Process

After production concludes, the obvious answer to any question is, will you have just one or two, and what flavor? All kidding aside, the next stage of the production of hard seltzers is to can the beverage.

The first stage of the canning process is to have stock aluminum cans rinsed and ready to be used. Once rinsed, the cans are next ready to be purged of air with an infusion of CO2. Once the air is purged from the cans, they are now ready to be filled with yummy, delicious hard seltzers.

As the cans are filled, they are now fitted with lids and pressed to create a CO2 seal. Once the caps are pressed, the next step is to crimp the can and lids to create a permanent seal. This stage is conducted with a crimping machine that spins the cans at a rate of up to 120 rpm while crimping the edges of the lid and can to create the permanent top of the can.

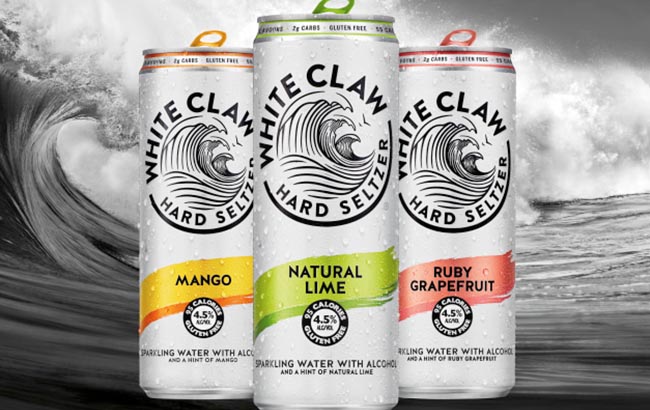

Once the cans are sealed, the final stage of canning is to have a design in place for labels. This stage is known as can sleeving and is what separates brands from each other. Just know that there are specific regulations regarding what has to be included on the label, such as volume, alcohol, and ingredients used.

We’ll Drink to That!

That’s about it in the process of making and canning hard seltzers. However, the ease of production and limited ingredients needed, coupled with the drink’s immense popularity, makes it a no-brainer for restaurants to consider making their own. Or for individuals, try making one at home and impress your friends!